Active rf circuits technology and applications

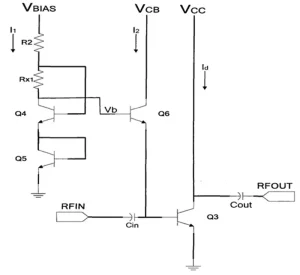

Active RF circuits are RF circuits that require an external power source to function properly. Such circuits usually contain components such as amplifiers, mixers, and voltage-controlled oscillators, and are capable

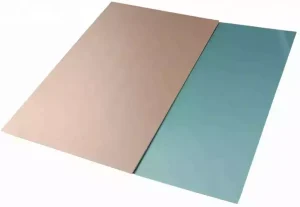

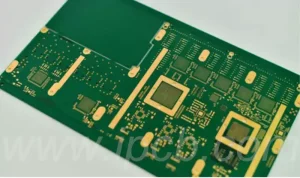

Properties and Applications of Nelco N4000 13

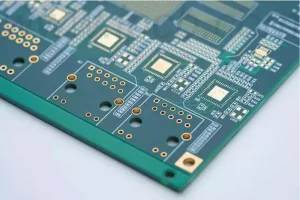

Nelco N4000 13 is a very high quality multilayer sheet that is carefully crafted from glass fibre and epoxy resin, with the number of layers varying between approximately 8 and

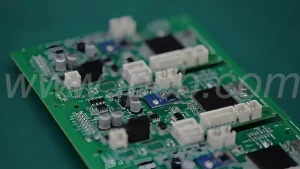

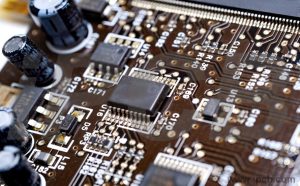

Core functions of hard drive printed circuit board

The hard drive printed circuit board is a key component of a hard disc. It consists of one or more layers of glass fibre substrates stacked on top of each

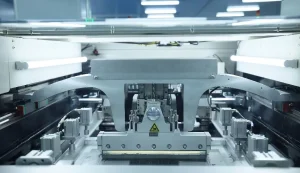

SMT High Temperature Soldering Technology

SMT high temperature soldering technology is a soldering method that uses peak soldering temperatures in excess of 220°C in the SMT (or Surface Mount Technology) process. This technique is typically

Cold solder joint problems and coping

A cold solder joint is a soldering phenomenon that occurs when the required minimum wetting temperature between the brazing material and the base metal is not reached, or when the

PCBA test fixtures: electronics manufacturing key pillar

PCBA (Printed Circuit Board Assembly) test fixture plays a vital role in the electronics manufacturing industry. Its main function is to provide physical support and electrical connection for the test

Comparison of DIP and SMT technology

DIP package assembly, also known as Dual In-line Package (DIP), is an assembly method that requires the pins of an electronic component to be inserted into a through-hole of a

Phone Circuit board RF layout strategy

A phone circuit board is a key component used for the connection and assembly of circuits inside a mobile phone. It is usually a thin board made of insulating material

teflon pcb laminate

The use of teflon pcb laminate has increased dramatically recently. There are many reasons for this change. One of the reasons is the rapid development of the electronics industry and

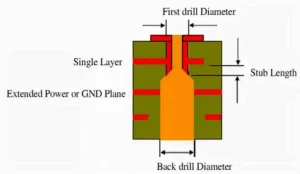

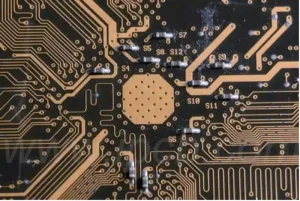

PCB backdrill technology analysis

PCB backdrill, also known as controlled depth drilling, is simply the process of drilling a hole from the back side of an already manufactured multilayer circuit board. However, this is

Printed circuit boards depaneling technology

In the mass production of printed circuit boards (PCBs), manufacturers often combine multiple individual boards into one large board, a process known as boardmixing, where multiple small boards are combined

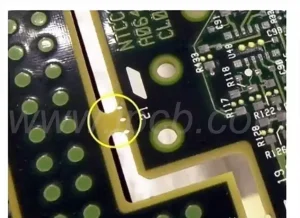

pcb microscope

A pcb microscope is a microscope specifically designed to observe printed circuit boards (pcbs). In the modern electronics industry, pcb microscopes play a key role in helping engineers and technicians

Efficient application of hot plate for pcb soldering

Hot plate for pcb soldering is an advanced soldering technique that is primarily used to securely attach electronic components to printed circuit boards (PCBs). This method utilises the heating function

Parasitic Resistance Factors Affecting Circuit Performance

Parasitic resistances are resistances that are not intentionally designed into a circuit, but are created due to circuit layout or component characteristics, for example. They are usually unavoidable and affect

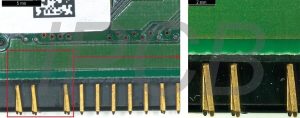

The role and wide application of soldering pins in PCB

In the field of modern electronic manufacturing, the welding process is an important step to realize the functions of electronic equipment. In the welding process, soldering pins, as one of

HDI technology changes the future of the PCB

HDI technology is a cutting-edge PCB (Printed Circuit Board) manufacturing process that offers the significant benefits of high-density layout, high reliability and high integration, with the PCB serving as the

AllFlex PCB Design and Applications

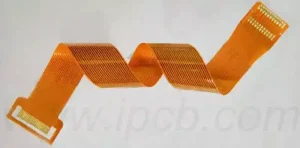

Allflex PCB, also known as Flexible Printed Circuit Board (FPC), is a type of circuit board that can be completely bent. Folded or curled circuit board. It consists of one

Flexible PCB Bending Radius Consideration

What is the bend radius of a flexible circuit board? The bending radius of a Flexible Printed Circuit Board (FPC) refers to the fact that when the FPC is bent,

HDI circuit board technology and material challenges

The stacked construction technique of HDI circuit boards allows multiple circuit layers to be interconnected by means of precisely tuned blind and buried vias, which are significantly smaller in diameter

High technology and cost for ELIC PCB

ELIC PCB is one of the HDI products, the full name is every layer interconnection, is the highest end of the HDI products. ELIC boards are commonly stacked for 8

Cirucit board labels and Labelled circuit boards

Circuit board labels are the PCB (Printed Circuit Board, Printed Circuit Board) technology based on the manufacture of high-frequency RFID tags. PCB tags can be divided into a variety of

pcb panel size

Common pcb panel sizes (which can be considered industry standards) include: 24” x 18”, 12” x 18”, and 24” x 9”. Note that these panels have 0.5” margins on all

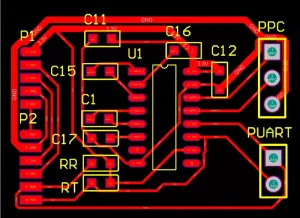

PCB layout rules and guidance

When designing a printed circuit board (PCB), following basic pcb layout rules is essential to ensure the functionality and performance of the circuit. The basic rules of PCB layout:1.According to

PCB Edge Plating Technology

PCB side plating, also known as pcb edge plating, is a copper plating that is applied from the top to the bottom surface of the board and along (at least)