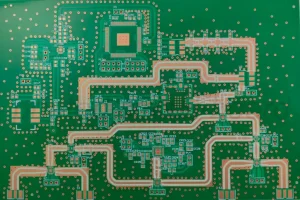

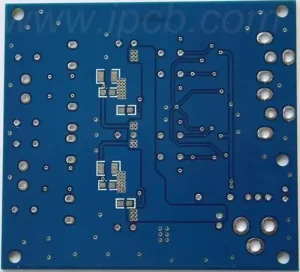

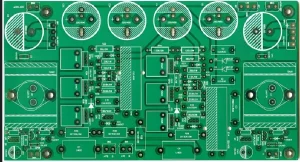

What are printed circuit boards used for

Printed circuit boards are indispensable basic components in modern electronic devices. Its applications are extremely broad, covering a wide range of industries such as industrial, agricultural, aerospace, automotive and medical.

Importance of Cleaning Copper Wire for Soldering

In the precision manufacturing of printed circuit boards (PCBs), the surface finish of cleaning copper wire for soldering is critical. These wires are a core component of the soldering process,

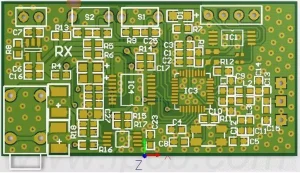

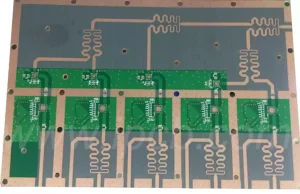

RF PCB Stackup Design Overview

RF PCB stackup involves combining multiple board layers in a specific order and structure to form a complex circuit board. This structure not only accommodates the different functions of the

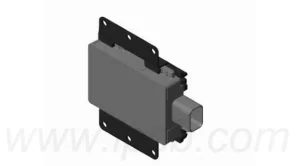

PCB RF connector design and function

A PCB RF connector is a key component used to connect an RF circuit board to other devices, usually on a printed circuit board (PCB). Its main function is to

LG Microwave PCB Board Design Considerations

The LG Microwave PCB Board is a key component in a microwave oven that is responsible for controlling the functions and operating status of the microwave oven. Often referred to

Characterization and Manufacturing of Prepreg PCB

Prepreg pcb, also known as prepreg, is a key material used in the production of multilayer printed circuit boards (PCBs). Prepreg consists mainly of a resin and a reinforcing material

The Role of Hot Plate in PCB Manufacturing

A PCB hot plate is a heating device that is used to heat PCBs by controlling the temperature and heating time.The process usually involves placing the PCB on a heated

pcb board scrap

pcb board scrap refers to the waste materials generated during the manufacturing or disposal of printed circuit boards (pcb). These wastes usually include the following types: Scrap generated during the

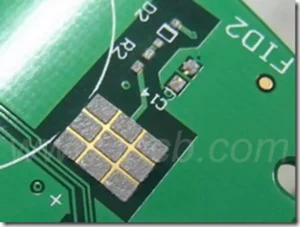

Chip on board ic technology

Chip on board ic refers to a system formed by pasting a chip directly onto a circuit board, usually in an unpackaged or simplified package.This technology allows electronic components to

The Role of Apex Regulator PCB in Modern Electronics

The development of electronic systems has created the need for advanced power management solutions, which are essential in ensuring that devices function optimally. At the core of these systems is

Mobile PCB Design and Manufacturing

Mobile pcb refers to printed circuit boards used in mobile devices (e.g., cell phones, tablets, portable chargers, etc.). Such boards are usually designed to be thin and lightweight and efficient,

pcb motor

A pcb motor, also known as a BLDC motor, is a three-phase brushless motor based on the Hall effect, which works by utilizing the current from an electronic controller to

Tin melting temperature on pcb soldering

Tin melting temperature is a key parameter in the soldering process and has a direct impact on the quality of the solder. Understanding the melting temperature of tin and its

Millimeter wave radar connector material selection

Millimeter-wave radar connector is specialized connectors for millimeter wave radar systems that provide low loss and high reliability in high-frequency signal transmission.They are widely used in automotive,driverless,and industrial automation applications

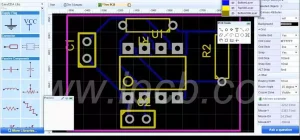

Selection and application of layouter pcb

Layouter pcb, also known as PCB design software, play a vital role in the circuit board design and manufacturing process. It helps engineers in the development of electronic products by

Key Factors in PCB Doppler Radar Materials

PCB doppler radar is a radar system that utilizes the Doppler effect to detect the position and relative velocity of moving targets. When the radar transmits a fixed-frequency pulse wave

The FR4 CTE Analysis and Applications

FR4 CTE (Coefficient of Thermal Expansion) is the degree to which FR-4 material expands in response to changes in temperature.FR4 is a substrate widely used in printed circuit boards (PCBs)

Understanding the Role of Guitar Pedal Circuit Boards

Guitar pedals are an essential tool for musicians who seek to shape their sound and add unique effects to their performances. At the heart of these pedals are guitar pedal

IC chip fabrication and testing process

IC chip fabrication is a complex and delicate process involving multiple steps, from design to production and ultimately packaging.Its essence is the integration of various electronic components onto a single

Role and Selection of Printed Circuit Board Parts

Printed circuit board parts is the process of connecting electronic components to the wiring of a printed circuit board. The traces or conductive pathways engraved in the laminated copper sheets

Introduction to smt prototype board

SMT prototype board is circuit board manufactured using surface mount technology (SMT), which covers the process of integrating and soldering electronic components by means of this modern technology.SMT technology is

pcb solder pins

The pcb board pins are an integral part of any electronic device, enabling smooth and reliable transmission of signals and power between different components on a printed circuit board. These

Understanding the Role and Function of an Elevator PCB Board

In today’s modern urban landscape, elevators have become an indispensable part of everyday life, particularly in high-rise buildings. From residential towers to commercial skyscrapers, elevators offer convenience, accessibility, and efficiency,

Introduction to RF Filter PCB

RF Filter PCB is circuit board specifically designed to process RF signals and are widely used in wireless communications, broadcasting, satellite, and other high-frequency applications. The main function of these