Differences in Frequency Bands for Automotive Radar PCB Antenna Design

All design differences between 24 GHz and 77 GHz automotive radar PCB antenna boards fundamentally stem from the distinct physical characteristics of the frequency bands themselves. Frequency determines wavelength, and

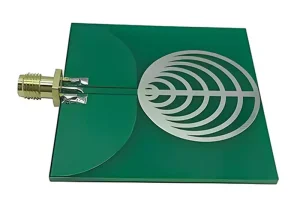

The Critical Role and Design Considerations of PCB Antenna Ground Planes

In wireless communications, antennas are of paramount importance, and the PCB antenna ground plane, as a critical component, influences multiple aspects of antenna performance. In wireless communications, pcb antennas are

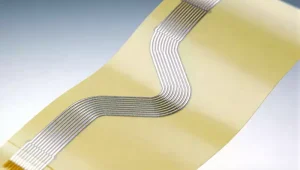

Application of Serpentine Antennas in Small Wearable Devices

Inside products such as smart bands, TWS earbuds, smartwatches, and health monitoring patches, there is a constant tension between extremely limited internal space and ever-increasing communication requirements. Serpentine antennas, with

Key Considerations for EMC Design of Antenna PCB

In antenna PCB design, electromagnetic compatibility (EMC) is a key factor in ensuring stable device performance and minimizing interference. As core elements of EMC design, layout and routing are not

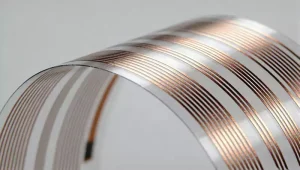

Four layer flexible circuit board

What is a four layer flexible board? FPC flexible boards can be used to manufacture four layer boards, but compared to double-layer or multi-layer FPC flexible boards, the manufacturing process

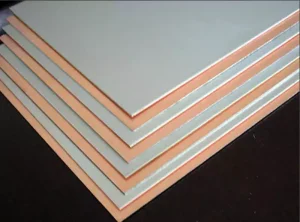

Selection of Rogers and FR-4 Substrates for Antenna pcb

FR-4 and Rogers, as the two most prevalent substrate materials in the antenna PCB sector, possess no inherent superiority or inferiority; their suitability depends solely on the application context. Selecting

Optimisation of the Solder Mask Layer for High Frequency Antennas

A high frequency antenna operates in the 300 MHz–300 GHz RF spectrum (corresponding to electromagnetic wavelengths of 1 m–1 mm). It is the core RF component responsible for bidirectional energy

Cost and Performance Comparison of PCB Antennas versus Ceramic Antennas

PCB antennas are directly formed by etching metal traces on the PCB substrate to create radiation units, utilizing the rigid material of the PCB for signal transmission and reception, without

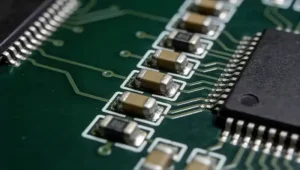

Controlling Drilling Damage in FR4 Substrates to Enhance PCB Quality

Mechanical drilling constitutes the core process for achieving interlayer electrical interconnections in PCBs, yet it remains the stage where FR4 substrates are most susceptible to microscopic damage. Under the combined

Why FR4 Plate Keyboards Are Gaining Popularity in Custom Mechanical Designs

The Role of FR4 Plate Keyboard in Mechanical Keyboard Structure In the structural design of mechanical keyboards, the plate (positioning plate) is a crucial intermediate layer connecting the switches to

Differences and Selection Between Aluminide and Alumina Ceramic Substrates

Ceramic substrates, as critically important materials within PCBs, play a pivotal role in enhancing PCB performance through their unique physical and chemical properties. Among these, aluminium oxide (Al₂O₃) and aluminium

4 layer PCB Layering Techniques for Achieving Extremely Low Noise Routing

As one of the most widely adopted specifications in the industry, the cost-effectiveness and practicality of 4 layer PCBs are beyond question. However, achieving low noise floor hinges not on

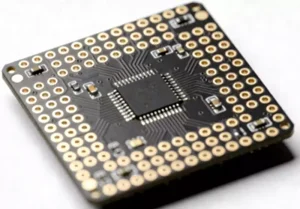

Via Form and Cost in PCB boards

PCB boards serving as the core carriers of electronic devices, see their performance and cost directly influenced by the precision of their design and manufacture. Via holes, as the fundamental

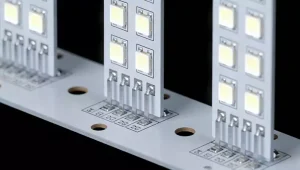

Ultra Thin PCBs Drive the Advancement of Wearable Devices

In recent years, the widespread adoption of smart wearable devices has significantly transformed people’s lifestyles and health management. From smartwatches and fitness trackers to smart glasses and medical devices, wearables

Why is PCB layout more decisive than routing in PCB design?

In the complex process of PCB design, PCB layout and PCB routing are two core stages that together determine the final performance and reliability of the product. However, during the

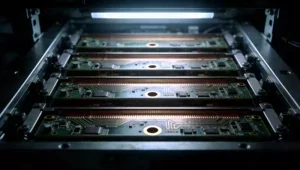

High Frequency Board Technology for 5G Base Stations

In the current era where 5G communication technology is reshaping the global information landscape with lightning speed, 5G base stations, serving as the “nerve endings” of network coverage, directly determine

4 layer PCB High-Efficiency Heat Dissipation Design Strategy

In the era where electronic devices are constantly evolving towards higher performance and greater integration, the heat dissipation issue of PCBs has become increasingly critical. Copper, with its outstanding thermal

Differences in 4 layer FPC bend design

Flexible Circuit Boards (FPCs), with their unique bendable properties, have become a key component in high-end applications such as foldable smartphones, wearable devices, and industrial robots. Among them, 4-layer FPCs

How does the thickness of PP film affect PCB impedance?

Precise control of interlayer spacing is the true key to achieving stable pcb impedance, and prepreg thickness is the “behind-the-scenes driver” that determines that spacing. How are interlayer spacing and

Controlled Impedance Design for FR4 High Speed PCB

For high-frequency or high-speed digital circuits, wiring on FR4 materials is no longer as simple as just connecting components. Impedance-controlled design directly affects signal integrity, electromagnetic compatibility (EMC), and system

Preventing reference plane gap hazards in 4 layer PCB Boards

In a 4 layer PCB board, although signal crossing over reference plane gaps may seem minor, it can trigger a series of issues such as signal distortion, electromagnetic interference (EMI),

Key Considerations for Differential Wiring Switching in 4 layer pcb

When routing differential wiring on 4 layer pcbs, inadvertent interlayer transitions can readily cause signal distortion and a sharp decline in product yield. Unlike single-layer or thick multilayer boards, the

Breaking Through with Ultra-Fine Circuit Design on HDI Boards

In the context of the PCB manufacturing industry’s upgrade towards high-end and miniaturization, HDI boards, with their unique technological architecture, have become the core carrier for solving the challenges of

Causes and Remedies for PCB Pad Detachment

The PCB pad, as a critical part connecting components to the PCB, directly determines the performance and stability of the entire circuit. However, in actual production and maintenance processes, pad