The Solder Paste Stencil Behind SMT Quality

In the entire process of SMT, precise printing of solder paste is the first step to achieve high-quality welding. To achieve this goal, a widely used and crucial tool is

PCBA mass production common problems and solutions

In the PCBA mass production process, due to the expansion of production scale and process complexity increases, often encounter some common problems. The following will explore these issues in depth

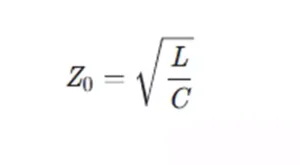

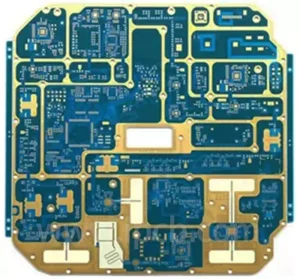

Difference and Calculation of Characteristic Impedance and Impedance

Characteristic impedance, also known as features impedance, is the pure resistance of a circuit or transmission line per unit length when the frequency tends to infinity. It is an inherent

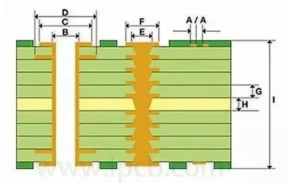

HDI pcb stackup structure and rational design

HDI PCB is usually manufactured using the stackup method, the so-called ‘stackup’ refers to the formation of complex multilayer structures through the stacking and compression of multiple layers of circuit

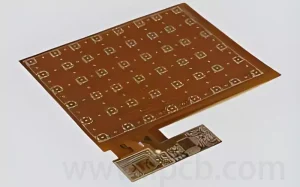

HDI Flex PCB Manufacturing and Application

HDI Flex PCB is efficient and reliable circuit board with multiple electronic components. They offer better electrical performance in a smaller package size due to the use of thin, non-conductive

Flexible PCB Board Bending Test

Flexible pcb board(FPC) is a flexible, thin and lightweight, bendable circuit connector made of polyimide, polytetrafluoroethylene and other polymer materials as the substrate, formed by chemical etching or laser stripping

The role of PCB board clamp and how to choose

PCB board clamp usually refers to fixtures used to hold PCBs (printed circuit boards) in place. In the production of electronic equipment, PCB board clamps are used to ensure that

PCB Circuit Board Printer Advantages and Applications

PCB circuit board printer, also known as circuit board printing machine or circuit board printing machine, is a device specially designed to print conductive patterns and components on circuit boards.

Manufacturing difficulties of hdi pcb

High Density Interconnect (HDI) pcb is widely used in modern high-end electronics due to their excellent performance and compact structural design. However, the manufacturing process of HDI PCBs is complex

Main difficulties in the production of aluminium pcba

Aluminium PCBA is widely used in high power density electronic devices due to its superior thermal performance and mechanical strength, but there are a number of manufacturing difficulties in its

Energy Harvesting PCB Layout and Manufacturing Essentials

Energy harvesting pcb (Printed Circuit Board) is a circuit board applied in energy storage devices (e.g. batteries, supercapacitors) to manage, protect and control the charging and discharging process of the

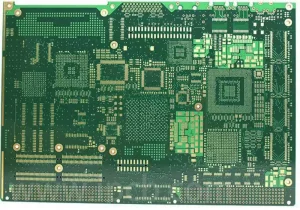

High multilayer circuit board manufacturing difficulties

High multilayer circuit boards usually refer to circuit board structures with 10 to 20 or more layers. Compared with traditional multilayer circuit boards, the complexity of their processing processes has

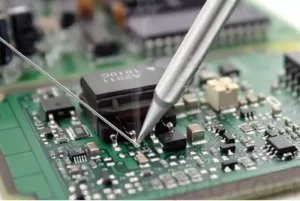

Comparison of wave soldering and selective soldering processes

Conventional wave soldering is a mature and widely used mass welding technology, by inserting plug-in components into the PCB board, and then the whole through the solder wave to complete

Wave soldering process control points

Wave soldering as a key process widely used in the field of electronic manufacturing, the stability and precise control of the process is an important guarantee to ensure the quality

High Voltage PCB Design Material Selection

High voltage pcb design has an important position in modern electronic equipment, especially in the fields of power electronics, industrial control and new energy vehicles. As it involves high voltage

Materials and characteristics of high current PCB connector

High current pcb connector is an electrical connector that can be connected and disconnected under high current and high voltage conditions, and is mainly used for connecting high power supplies

Laser engraving pcb board technology

Laser engraving pcb board is the process of processing and engraving circuit boards using laser technology. Laser engraving pcb board mainly uses the laser’s high energy density and precise control

Circuit board assembly machine

Circuit board assembly machine is a very important equipment in the semiconductor industry, which is mainly used to automate the assembly of electronic components and circuit boards. According to its

Double sided PCB board assembly process

In the field of electronic manufacturing, double-sided PCB board assembly by virtue of its high integration, small size and other advantages, widely used in various types of electronic products, from

Flow of custom pcba

Custom PCBA refers to the customised design and production of PCBA products according to customer requirements. This includes selecting the right components for the specific application, designing a board layout

Difference between high frequency PCB and high speed PCB

High frequency pcb and high speed pcb belong to the same PCB circuit boards used for signal transmission, however, there are significant differences between the two in the actual application

Moisture Sensitive Level and Components Applications

The MSL (Moisture Sensitive Level) standard is a classification system used by the electronics industry to assess the sensitivity of components to moisture, which classifies components into eight different levels

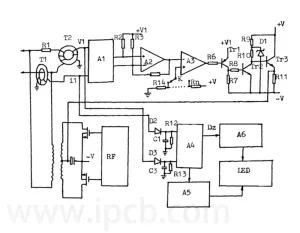

RF Circuit Design Principles and Key Points

The fundamentals of RF circuit design include: RF Circuit Layout PrinciplesWhen designing an RF layout, priority must be given to meeting the following general principles: (1) As far as possible

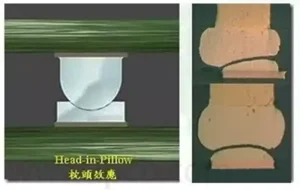

Principle and Prevention of Pillow Effect on Solder Joints

Solder Joint Pillow, also known as the pillow effect (Head-in-Pillow, HIP), is an undesirable phenomenon in which the solder balls of BGAs, CSPs and other components fail to fully fuse