Printed Circuit Board RF Chip

Printed circuit board radio frequency (RF) chip, also known as printed circuit board rf chip, is the core components in the field of wireless communications and are responsible for converting

Double sided PCB board characteristics and material

A double sided PCB board (or 2-layer PCB) is a printed circuit board coated with copper on both sides, top and bottom. There is an insulating layer in the middle.

Bluetooth pcb board design and application

Bluetooth pcb board is a key electronic component that plays an important role in modern technology. Bluetooth pcb board is a wireless communication technology that transmits data and information through

Analysis and prevention of PCB warping and twisting

In printed circuit board (PCB) manufacturing, pcb warping and twists are often seen as the top defects in nonconformities, which often stems from a lack of in-depth understanding of their

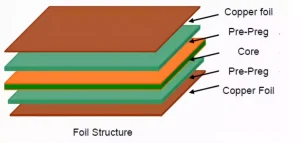

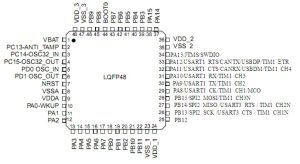

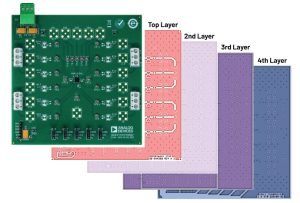

Layers of a pcb and structure

Layers of a pcb is the copper layer, PCB is made of copper layer + substrate compression and become, in addition to a single panel is a layer of copper,

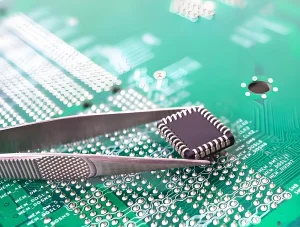

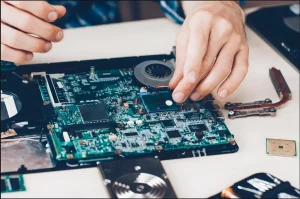

How to Remove IC Chips

In the process of repairing and modifying electronic equipment, mastering how to remove IC chips is an important skill. IC (integrated circuit) chips are widely used in a variety of

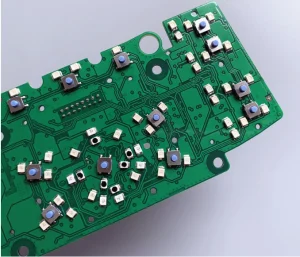

Exploring the optimisation of pcb button materials

PCB buttons are everywhere we live and work, from mobile phones and TV remotes to computer keyboards, keys are an important medium of interaction between us and our devices. PCB

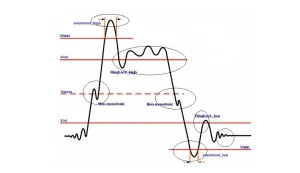

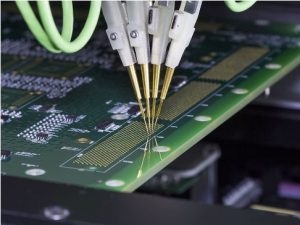

What is signal integrity?

In modern electronic equipment, high-frequency and high-speed performance is gradually becoming the industry standard. People have higher requirements for the speed, precision and reliability of various electronic products, which makes

printed circuit board fabrication

Main Steps in Printed circuit board fabrication:To get a clear picture of the printed circuit board fabrication process, let’s take a step-by-step look at how a PCB develops from an

What is RoHS PCB Board

Printed circuit boards (PCBs) are the foundation of modern electronics, and their manufacture involves a wide range of materials and chemicals. However, as environmental awareness grows, global requirements for PCB

ceramic pcb vs fr4

How to choose between ceramic pcb vs fr4? This article will show you how to choose. Ceramic pcb: a circuit board made of ceramic material, also known as ceramic PCB

What is Couple in RF PCB

In modern electronic equipment, the design and manufacture of radio frequency (RF) PCBs are receiving more and more attention. With the rapid development of wireless communications and a variety of

audio ic board

The audio ic board is one of the important components in the speaker equipment, and it undertakes many key functions. First, the audio IC board is responsible for receiving the

3 layer pcb

In the electronics industry, pcb plays a vital role. It is the support of electronic devices and the key to circuit connection. In the development history of pcb, multi-layer pcb

Automotive Printed Circuit Board Repair

Introduction With the continuous progress of automobile technology, the electronic systems in automobiles are becoming more and more complex. The role of printed circuit boards (PCBs) as a core component

2 layer flex pcb

2 layer flex pcb is a printed circuit board designed to be flexible and bendable. Unlike traditional rigid circuit boards, flexible circuit boards are made of thin and flexible materials

What is the ground pin

Pins have various functions, and the most common ones are power pins, ground pins, input pins, and output pins. The power pin provides the power supply voltage required by the

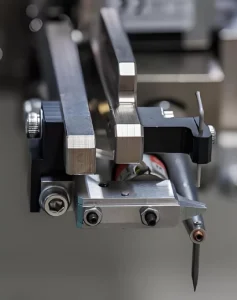

What is PCB Pinner and Importance

A pinner in the context of printed circuit board (PCB) fabrication is a key tool used during the assembly process to ensure precise and accurate positioning of components on the

What Does the Abbreviation PWB Stand For?

In the world of electronics and manufacturing, abbreviations are often used to streamline communication and enhance efficiency. What does the abbreviation PWB Stand For? One such abbreviation, “PWB,” is commonly

load board pcb

Load board pcb is a device used to test and verify the performance and functionality of electronic equipment. It can simulate real working conditions and load test the device to

simple pcb layout

General rules of pcb layout, in pcb design, simple pcb layout refers to the planning of how to place electronic components on printed circuits and the process of placing electronic

pcb wire soldering

pcb wire soldering is the process of soldering on a printed circuit board. The process involves connecting wires or other components to the pcb, usually by heating the solder to

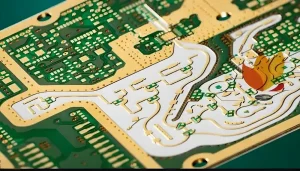

The Role of Custom PCB Board Printing in Modern Electronics

In the rapidly evolving world of electronics, custom PCB board printing has emerged as a vital process that facilitates the creation of highly specialized electronic devices. This process involves designing

Advancements in CNC PCB Drilling Machine Technology

The CNC PCB drilling machine has become an essential tool in the world of printed circuit board (PCB) manufacturing. As the demand for intricate designs and high-quality boards continues to