IC chip fabrication and testing process

IC chip fabrication is a complex and delicate process involving multiple steps, from design to production and ultimately packaging.Its essence is the integration of various electronic components onto a single

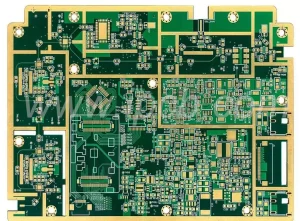

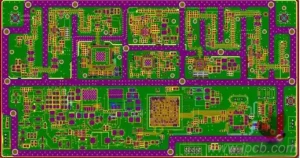

Role and Selection of Printed Circuit Board Parts

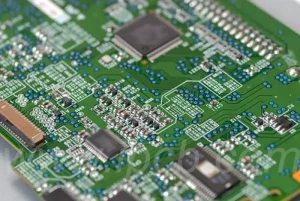

Printed circuit board parts is the process of connecting electronic components to the wiring of a printed circuit board. The traces or conductive pathways engraved in the laminated copper sheets

Introduction to smt prototype board

SMT prototype board is circuit board manufactured using surface mount technology (SMT), which covers the process of integrating and soldering electronic components by means of this modern technology.SMT technology is

pcb solder pins

The pcb board pins are an integral part of any electronic device, enabling smooth and reliable transmission of signals and power between different components on a printed circuit board. These

Understanding the Role and Function of an Elevator PCB Board

In today’s modern urban landscape, elevators have become an indispensable part of everyday life, particularly in high-rise buildings. From residential towers to commercial skyscrapers, elevators offer convenience, accessibility, and efficiency,

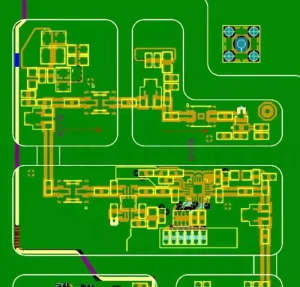

Introduction to RF Filter PCB

RF Filter PCB is circuit board specifically designed to process RF signals and are widely used in wireless communications, broadcasting, satellite, and other high-frequency applications. The main function of these

Strategies for RF circuit board design

RF circuit board design is an important technology in the development of modern electronic equipment, widely used in wireless communications, radar, intelligent devices and other fields. Due to the unique

Introduction to Arcade PCB

Arcade PCB is printed circuit boards specifically designed for use in arcade game machines and are responsible for connecting and controlling the various electronic components of the game. These boards

Importance of PCB Glass Transition Temperature

The PCB glass transition temperature (abbreviated Tg) is the temperature at which a material changes from a solid (glassy) state to a soft (rubbery) state. In other words, this temperature

The Future of Eco-Friendly Electronics with Halogen Free PCBs

As environmental concerns continue to drive change across industries, the electronics sector is also moving toward greener and more sustainable practices. One of these initiatives is the production of halogen

Manufacturing process for multiwire PCB

Multiwire PCB usually refer to boards that use multiple wires for signal transmission in the design of the circuit board. This technology allows more complex circuit designs to be realized

Optimizing LED PCB Footprints for Performance and Reliability

Printed Circuit Boards (PCBs) are fundamental in modern electronics, providing the necessary framework for connecting and supporting electronic components. Light Emitting Diodes (LEDs) are among the most widely used components

bluetooth pcb board

What is a Bluetooth module?Bluetooth module is a kind of integrated bluetooth pcb board, mainly used for wireless network communication, according to the function can be divided into the classic

Arlon Electronic Materials Overview

Arlon Electronic Materials is a distinguished name in the realm of high-performance electronic materials, particularly within the domain of printed circuit boards (PCBs). The company’s extensive portfolio and commitment to

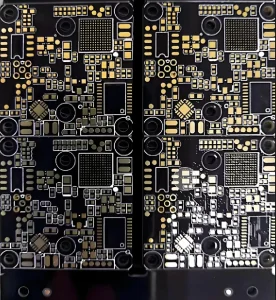

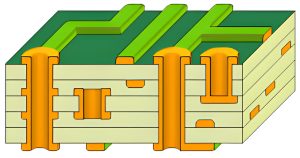

What is ceramic multilayer pcb?

Ceramic multilayer PCB board refers to the multilayer circuit boards used in electrical products, multilayer boards with more single-sided or double-sided wiring board. With a double-sided for the inner layer,

Advantages of low cost PCB boards

Low cost PCB boards are printed circuit boards whose production and assembly costs have been reduced by optimizing the design and production process. Such PCBs still maintain relatively high standards

Chip resistors are key components

What is a chip resistor? A chip resistor, also known as a surface mount resistor (SMD Resistor), is a type of resistor designed for surface mount technology (SMT). Compared to

The role of epoxy resin in pcb manufacturing

Epoxy resin is a polymer material that is widely used in circuit board manufacturing and serves several important functions.It not only provides mechanical support and connections for electronic components, but

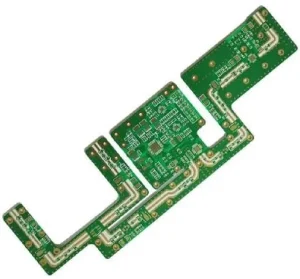

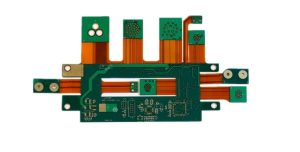

rigid flex pcb manufacturers

What is Rigid-Flex Circuitry?The birth and development of FPCs and PCBs has given rise to the existence of rigid flex pcb manufacturers. Rigid-Flex PCB technology has its origins in the

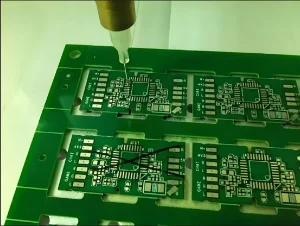

SMT pin transfer application and selection guide

An smt pin transfer is a connector used in surface mount technology (SMT), primarily to enable electrical connections between circuit boards. The design of the device enables components to be

Importance of Air Conditioner Circuit Board

The air conditioner circuit board is the control center of the air conditioning system and is responsible for collecting signals from the remote control or sensors and issuing commands based

RF PCB Design Optimization Tips

In modern electronic products, RF PCB design is a core aspect of ensuring device performance and functionality. With the development of wireless communications and Internet of Things (IoT) technologies, the

ICT Testing in Electronics Manufacturing

ICT Test (In-Circuit Test) is a widely used in-line testing method in the electronics manufacturing industry, designed to identify defects and bad components in the production process by testing the

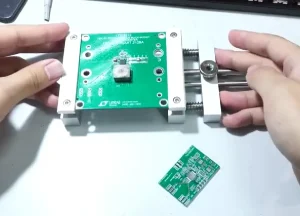

Efficient Production with the Right PCB Board Clamp

Printed Circuit Boards (PCBs) are foundational components in modern electronics, enabling the connection and functionality of various components within a device. The manufacturing and assembly processes of PCBs require precision